Tours

Building Tours

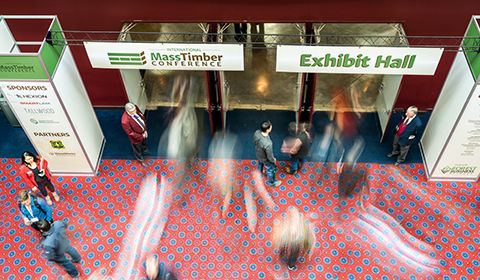

The highly anticipated mass timber building and facility tours promise outstanding buildings, mass timber manufacturing, and plenty of networking with global professionals on this consistently sold out event

Cost

$350/person

Date

March 31, 2026

Details

- Coach transportation provided (to and from the Oregon Convention Center).

- Lunch provided.

- Blue Star Donuts (Portland’s gourmet favorite) and hot coffee/tea served before departure. Courtesy of Henkel.

- Safety helmets, vests, and other protective equipment provided.

To purchase, first register for an attendee pass and then select your preferred tour pass.

Important

- All of the tours happen simultaneously, so you must choose one or the other.

- All tour attendees must ride on the provided buses — no riding to and from tour stops in separate vehicles is allowed.

- We may tour one or more active construction site(s), so attendees must wear long pants and sturdy, close-toed shoes such as hiking or work boots. Anyone wearing short pants, skirts, dresses, raised heels, tennis shoes, open toed shoes or other attire not appropriate for an active construction site may be excluded from certain stops.

- The weather in Oregon can be cold and rainy, so come prepared with a warm jacket, warm hat, gloves, and rain jacket. Sunglasses can also come in handy at times.

In Person Tours

View Tour #1Tours: Buildings & Manufacturing

In-Person TourTuesday | March 31, 2026

Explore the Portland area and surrounding locations in western Oregon and Washington, and the latest and greatest mass timber buildings, in this exciting pre-conference outing. Learn from and connect with project architects, designers, engineers, developers, and builders.

Blue Star Donuts (Portland’s gourmet favorite) and hot coffee/tea served before departure, courtesy of Henkel. Lunch provided.

Tour details available fall 2025.

+ VIEW DETAILS

View the Agenda

View the Agenda

Book a Building Tour

Book a Building Tour

Book Your Exhibit Space

Book Your Exhibit Space

Explore the Exhibit Hall

Explore the Exhibit Hall

Become a Sponsor Today

Become a Sponsor Today

View Sponsors & Partners

View Sponsors & Partners

Call for Content

Call for Content

Purchase Report

Purchase Report