How To Create a Carbon Sink City (2024)

David Atkins, Sustainabilist, Forester, Ecologist, Writer

Droughts, failed crops, wildfires and smoke pollution, more intense hurricanes, typhoons and floods, and stifling heat domes around the world over the past decade have made the reality of changing climatic conditions personal for everyone on the planet.

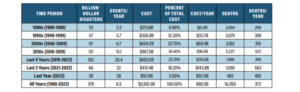

The economic consequences and the rate at which costs are rising are staggering. Table 1 shows that in the 1980s, the number of climate disasters causing more than $1 billion in damage averaged 3.3 per year, and the average total cost was $21.4 billion a year. From 2020 to 2022, the number of events averaged 20 per year at an average cost of $152 billion a year. The total cost for those 3 years was nearly $500 billion.

A study1 released November 2022 examined the social cost of fossil carbon emissions and conservatively estimated it to be $185/ton. The US EPA included an updated social cost of carbon (SCC)2 at $190/ton, in the new methane regulations, effective this year. The SCC attempts to quantify the cost to society of fossil carbon emissions. It includes the cost of deaths and illnesses caused by heat, smoke inhalation, and lung and heart diseases; it also includes the costs of natural disasters to the government, to insurance companies, and to businesses as a result of these events and others.

These costs are all externalized from the price of fossil fuels; the companies that are the source of the carbon emissions don’t include these costs in a barrel of oil, a ton of coal, or a thousand cubic feet of natural gas. But we are all paying the price through our insurance rates and taxes. If this price was internalized into the cost of every fossil fuel product, it likely would create a powerful market incentive to use products with the lowest carbon footprints because they would become the cheaper alternatives.

Over the years, keynote speakers at the International Mass Timber Conference (IMTC) have painted a vision of urban areas as carbon sinks rather than sources, and the speakers regard mass timber as the cornerstone of accomplishing that. In addition, they have talked about mass timber feeding our biophilic being, how natural materials in our work and home spaces enhance our mental and physical health, our productivity, and our safety. They have also presented the idea of a circular economy where “wastes” from one activity become the feedstock of another. A mass timber building could be designed and assembled in a way that it can be deconstructed, and the elements reused rather than landfilled.

The IMTC has been a source of inspiration for the possible, like urban sinks, and just as important, a source of practical information about how to implement them. Mass timber has come a long way in a decade around the world, and yet it is still early in its growth curve and not without growing pains along the way. Each setback has resulted, however, in learning, adapting, and improving.

The structural elements of a building account for about 80 percent of its embodied energy; therefore, the use of mass timber is the cornerstone of a building as a carbon sink. What other elements need to be incorporated to achieve a carbon-negative city? What are the specific opportunities? Who is responsible? What are the right carrots and sticks to change behavior?

Mass timber is one of many renewable, sustainable products that can store the naturally captures carbon from photosynthesis, as identified in chapters 2 and 9.

Wood Fiber Insulation

Reducing fossil energy consumption is crucial to achieving the 2015 Paris Agreement goal of staying below a 1.5°C global temperature increase. But reducing all energy consumption is important because there are consequences and risks associated with every form of energy production and consumption, whether renewable or not. More news outlets are reporting threats to the supply of crucial minerals, including some sourced from countries that are not very stable, and some sourced from countries that may want to gain economic or political leverage. New, energy-efficient buildings and the retrofitting older buildings are vital to the economic and national security of every nation.

Insulation can dramatically reduce our operational energy consumption and greenhouse gas emissions. The type of insulation used, however, has its own energy and carbon considerations

Wood fiber insulation in the form of loose fill, batting, and rigid board is now made in North America. TimberHP in Madison, Maine, is the first company in the US to produce wood fiber insulation, and it went into production in 2023. That form of insulation has been readily available in Europe for many years. One of the many benefits of its use is that it creates a long-lived carbon storage product from sawdust, slab wood chips, and small trees that need to be thinned out of forests to grow and manufacture sawlogs. The carbon in the insulation is stored for the life of the building along with structural wood components, and its use reduces the building’s operating energy. Additional manufacturing plants are in the planning stages in North America. Borate, a naturally occurring mineral solution, is added to the insulation to help protect it from insects, mold, and rot. It also acts as a fire retardant.

Nanocellulose Concrete

The use of nanocellulose in small quantities can have a large effect on the carbon footprint of concrete. You might have heard that if concrete were a country, it would be the third largest emitter of fossil carbon in the world, behind China and the US.3

The US Endowment for Forests and Communities and the US Forest Service’s Forest Products Laboratory have developed partnerships that are working to commercialize this material. Nanocellulose Concrete has been used in demonstration bridges, sidewalks, curbs, gutters, and parking lots. A 20-acre reservoir was created by a nano-concrete dam in Georgia in 2024.

It is not readily available commercially, however, for a variety of reasons, but primarily because the recipe for concrete varies from location to location. The Recipe must be tested and adjusted for it to achieve the desired greenhouse gas (GHG) reductions.

When a 5-gallon bucket of 10 percent solution nanocellulose or a half-gallon of nanocellulose is added to an 8-ton concrete truck, it can reduce GHG emissions by about one-third, according to research done by the Forest Products Laboratory. It has been demonstrated in multiple parts of the US. The addition of nanocellulose is simple, once the local recipe is defined.

Adoption could be quick if the appropriate support mechanisms are established. As with many new, the challenge is to ramp up the demand to support the development of a full-scale manufacturing plant that can meet the needs of multiple commercial-scale projects. In addition, work to adjust the recipe to fit local and regional concrete formulas is needed. A joint effort by city, state, and federal governments can help concrete companies and developers jump-start the process by requiring it in a portion of all new sidewalks, gutters, streets, highways, and public building foundations.

Mass timber faced these same challenges less than 10 years ago in the US and Canada. Industry and government worked together to raise awareness, fund testing, change codes, and get mass timber to the commercial stage. It is prepped for continued rapid growth.

Biochar: Biological Carbon

People have charcoaled wood and other biomass for millennia. It has been used as an energy source and as a soil enhancement to improve the long term productivity of fiber and crops.

Technological advances have improved the efficiency of production and almost eliminate smoke pollution. Biochar is carbon that is very stable and, therefore, a powerful carbon capture and storage technology.

Graphene carbon sourced from biochar produces more efficient batteries. Charging is 5 times faster4 than when current minerals are used. BioGraphene Solutions (BGS) in Ontario, Canada, has a patent pending on its production process. The company intends to use the carbon to replace bitumen in asphalt, membranes, concrete, and How to Create a Carbon Sink City Other products to reduce their carbon footprints. The drawback is price, so it is only being used in small batteries for electronics. But costs are coming down as production techniques improve, and work to scale up production is underway.

The incorporation of solar panels and batteries in buildings and energy systems can reduce the amount of energy that must be imported to urban areas.

Thermoplastics made of biochar allow a building plumbing system and its siding to become a carbon sink instead of a source. Made of Air, based in Berlin, is moving these products forward. But the company also needs to scale up production and have the right set of incentives.

Biochar has been found to reduce the carbon footprint of concrete, as does nanocellulose. The potential synergy of using both is being researched.’

Opportunities exist to use urban biomass to produce energy for buildings and biochar for local uses.

Billion-Ton Study

As these biobased solutions surface, some people are concerned that the level of demand will incentivize overuse, wiping out forests and grasslands, and depleting our soils. In the US, the question of raw material supply often has been analyzed and reported in what is colloquially known as the Billion-Ton Study by the Departments of Energy And Agriculture.5

In the early 2000s, the question was posed as to whether the US had a billion tons of biomass available to develop alternative fuels for airplanes, ship-, large trucks, and other equipment that is hard to electrify. The short answer was yes. This analysis has been updated and expanded several times in the intervening years. The focus of the most recent study is product-agnostic; it provides information about the potential productivity and supply of biomass for any number of uses, including nanocellulose, biochar, energy production, and more.

In the Western US, tens of millions of dollars are being spent to thin millions of tons of trees to reduce wildfire risk and make the forests more resistant and resilient to a variety of disturbances. Most of that material is piled and burned.

The US is a long way from any kind of a shortage of fiber. Rather, the problem is disposal of excess trees by burning, which is adding GHG and black carbon emissions to the atmosphere.

Urban Forests

The vegetative abundance, or lack thereof, in our urban environments can have profound effects on energy use, carbon capture and storage, human well-being (physically, mentally, and emotionally),the cleaning and storing of stormwater runoff, creating wildlife habitat, and reducing crime rates.6 The latter comes from a study by the National Institutes of Health in 2019.

Designing urban swales full of trees and shrubs can help reduce flooding while also cleaning the water of pollutants from street and sidewalks. Developers can help achieve an urban carbon sink, and urban forests are part of that. Not only do the trees capture and store carbon, but when the trees must be removed, they can be used for a variety of products, How to Create a Carbon Sink City From furniture and flooring to biochar, energy, mulch, and compost. No technology learning curve comes with this solution; urban foresters, landscape architects, and others know how to design landscapes to reduce energy demand in buildings.

District Energy in St. Paul, Minnesota, uses urban tree and shrub waste as its fuel. Built in the early 1990s, it heats more than 30 million square feet (about the area of Central Park in New York City), cools over 20 million in the summer, and generates 25 megawatts of electricity. It was modeled after systems in Sweden.

Seattle, Washington, and Montpelier, Vermont, also have downtown district energy systems. In Europe, these systems are too common to try and list them. The diversion of green waste from landfills saves money and reduces methane emissions. To Create these systems requires an understanding of how these long-term investments help reduce costs we have externalized. Because they are externalized, we ignore them. But we pay for them anyway.

One of the newest creations in this urban greenscape is displayed in Figure 1. In Milan, Italy, 2 new buildings7 incorporated green rooftops, balconies, and more. With the vertical arrangement a multiplier effect of vegetative cover far exceeding the footprint of the building was achieved. This level of greenery has a design learning curve, but it has been demonstrated.

Waste Management: Composting

US society spends billions of dollars on waste management,8 from trash to sewage disposal, and then we spend more to create fertilizers for our gardens, farms, and city parks. What if we closed the loop and turned our waste into valuable products like green methane and soil amendments? Composting, whether through aerobic or anaerobic digesters, can take sewage and transform it into useful products while reducing the need for new or expanded sewage treatment infrastructure. The PAE Living Building Challenge structure9 toured as part of the 2023 IMTC demonstrated the technology for a single building, but to make this effective at scale and realize the potential savings for infrastructure costs, local, state, and federal governments need to create the incentives and disincentives.

As described above, closing the loop with our urban forest residues to create energy, and potentially biochar, requires recognizing who is paying the costs and what resources we are wasting that could be converted to valuable products. As when the social costs of carbon are disconnected from the sources, somebody else pays for the consequences. A similar thing happens with our waste stream. We make poor investments and miss opportunities to have a by-product rather than waste. Transitioning from a linear approach toa circular one is a challenge—until we create the right set of carrots and sticks to change behavior. Although not part of structures, the streets, sidewalks, and modes of transportation that move people from place to place are another piece of the built environment with a large carbon footprint. Some new developments in addition to nano-concrete include the use of nanocellulose in tire manufacturing to decrease rolling resistance and require less energy to move bicycles, buses, and cars.

Bridges all over the world were originally built with wood and often replaced by steel and concrete in the 20th century. Scandinavian countries have shown the world how wood can return as a primary construction material for bridges. Nordic In Canada is following their lead in North America (see Figure 2). The strength to weight ratio advantages of wood allow for greater payloads and have excellent durability and lifespan advantages.

The development of Sustainable Airp10 from biomass continues to improve and can help reduce the carbon footprint of flying between urban settings. Several tests around the world in the past 2 years have flown planes using 100 percent SAF.

Who Is Responsible, and How Do We Incentivize Change?

To achieve the vision of cities as carbon sinks, we need to change our behaviors. All of us are responsible individuals, but that is insufficient; we must also act collectively through our local, national, and international businesses, governments, and especially partnerships between governments and businesses. Overcoming the inertia of patterns and habits that are decades old is not easy. We need the appropriate incentives and disincentives to motivate, encourage, and prod the changes desired.

If we are paying for putting fossil carbon into the atmosphere through extreme storm damage, health costs, and more, why not incorporate the cost fossil carbon imposes on society into every product that uses it? Producers of polystyrene insulation products don’t pay the cost of their use of fossil carbon greenhouse gas emissions to create their products. Yet society is paying for it through our insurance rates, taxes, health costs, and repairing infrastructure damaged by extreme weather events.

If every user of fossil carbon had to internalize the cost they are imposing on society, the price of their products would have to reflect that. Products With little or no fossil carbon would have a competitive advantage with their lower prices; consumers would likely buy the products with lower costs and lower carbon emissions content. The use of market-based financial rewards would change our choices, and we likely would shift to low-, no-, or negative-carbon products.

Legislation introduced in the US House of Representatives, the Energy Innovation and Carbon Dividend Act, in September 2023 would achieve these market signals. Canada has implemented such a system. The EU has a price on fossil carbon and is moving to impose a carbon border adjustment on imports from countries that do not have a similar system.

To help kick-start new markets, city, county, state, and federal governments can embrace new concrete and asphalt products by specifying that contracts must use nanocellulose and/or biographene. They Can specify renewable, negative-carbon insulation products. Start-ups are riskier than established businesses, but most people are concerned11 about the changing climate conditions and the costs they are imposing on all of us. What is riskier—doing the same thing with accelerating billion-dollar extreme weather events, or using new tools and products in our urban built environments?

FIGURE 2: MASS TIMBER BRIDGE REDUCES THE USE OF CONCRETE AND STEEL // Source: Nordic.ca // Credit: ©Stéphane Groleau

As you might have noticed, all these products can come from forests: urban, agroforestry, natural forests, and production forests. Everything we use is either grown or mined. We need both, but the more we can use renewable, sustainably grown materials, the smaller our carbon footprint will be—and the more resilient, resistant and adapted our forests will be to changing climatic conditions. This is explored more in chapter 9.

Mass timber is a cornerstone product for achieving urban carbon sinks, but we need all these other products as well. The trees we do harvest need to be used for their maximum benefit, from the bark and sawdust to the piles of tree residues in the forest after logging, as well as the sawn lumber that goes into mass timber.

This biophilic, circular economy is a perfect(wooden) bridge across the so-called urban/rural divide. Instead of a divide, we are creating a symbiotic relationship where both areas can thrive by supporting each other. The path to the urban sink is unfolding before us.

1 https://www.nature.com/articles/s41586-022-05224-92

2 https://www.nytimes.com/2023/12/02/climate/biden-social-cost-carbon-climate-change.html

3 https://biographenesolutions.com

4 https://biographenesolutions.comproducts

6 https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6950486/ping

7 https://www.stefanoboeriarchitetti.net/en/project/vertical-forest/

8https://www.statista.com/topics/2630/waste-management-in-the-united-states/#topicOverview

9 https://www.pae-engineers.com/about/pae-living-building

10 https://www.energy.gov/eere/articles/lab-sky-five-things-know-about-biofuel-powered-flights

Download PDF

View the Agenda

View the Agenda

Book a Building Tour

Book a Building Tour

Book Your Exhibit Space

Book Your Exhibit Space

Explore the Exhibit Hall

Explore the Exhibit Hall

Become a Sponsor

Become a Sponsor

View Sponsors & Partners

View Sponsors & Partners

Reserve Hotel Rooms

Reserve Hotel Rooms

Discounted Plane Tickets

Discounted Plane Tickets

Read Case Studies

Read Case Studies

Download Past Reports

Download Past Reports