Freres Engineered Wood’s Plywood Warehouse (2025)

THE 58,000-SQUARE-FOOT MASS TIMBER WAREHOUSE MIMICS TILT-UP CONCRETE CONSTRUCTION

Source: CD Redding Construction; Credit: Ian Koenig with 365 CREATIVE CO

Project Owner: Freres Engineered Wood

Project Location: 47842 E Lyons Mill City Dr., Mill City, OR 97360

Completion Date: October 7, 2024

Architect/Designer: Crow Engineering

Mass Timber Engineer/Manufacturer: Crow Engineering / Freres Engineered Wood

General Contractor: CD Redding Construction

IN 2024, FRERES Engineered Wood used their patented Mass Ply products to construct a new plywood warehouse, showcasing wood’s ability to compete with traditional steel and concrete construction methods for industrial warehouse buildings. The innovative mass timber structure represents yet another sustainable improvement in the larger construction industry.

“As it is now, you only have two opportunities for warehouses: concrete tilt-up construction or pre-engineered metal buildings,” said Kyle Freres, the company’s vice president of operations. “There’s been a lot of exploration to see if wood can provide a viable alternative to these methods, and the new mass timber warehouse demonstrates that wood can offer a quicker and more effective means of constructing large-format warehouses.”

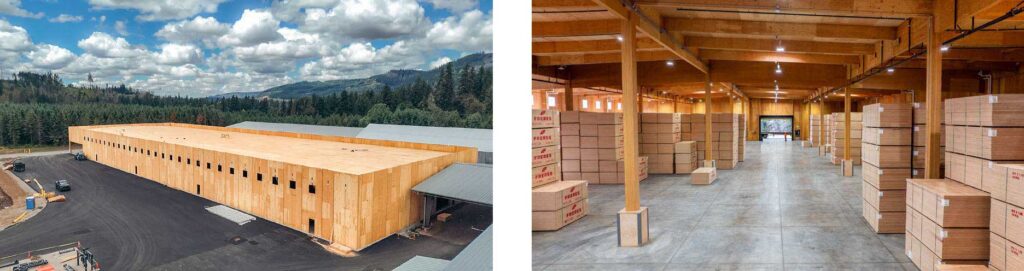

LEFT — FRERES ENGINEERED WOOD’S PLYWOOD WAREHOUSE, BEFORE CLADDING

RIGHT — THE WAREHOUSE FEATURES A 40-FOOT-BY-48-FOOT GRID

Source: CD Redding Construction; Credit: Ian Koenig with 365 CREATIVE CO

The 58,000-square-foot mass timber warehouse mimics tilt-up concrete construction, but the structural elements are entirely Freres Wood’s patented Mass Ply Panels (MPP) and Mass Ply Lams (MPL). The building features a specific 40-footby- 48-foot grid, with space for 4 truck loading stations, 2 tarping stations, and storage for 6,000 units of plywood.

“Most mass timber projects are built on a much smaller grid and don’t have this type of open floor space, so getting this span built in with the structure is unique,” Freres said.

In addition to the building’s impressive grid span, the construction team was able to save time by installing prefabricated Mass Ply products, thereby cutting costs. In fact, the Freres Wood team estimates the warehouse’s mass timber design allowed them to complete the project 3 months faster than they would have with a traditional concrete tilt-up method.

Finally, by replacing concrete and steel construction methods with wood alternatives, Freres Wood avoided approximately 429 metric tons of greenhouse gas emissions, representing a total potential carbon benefit of 1,539 metric tons. These measurements are the equivalent of taking 325 cars off the road for a year or saving the energy necessary to operate 163 homes for a year.

“We are thrilled at the potential for wood to compete directly with concrete and steel industrial building construction in the future,” Freres said. “We believe the biophilic nature of all-wood structures has the potential to improve the well-being of those living and working within them. Additionally, we hope these new mass timber designs will support the growing trend toward sustainable, renewable alternatives in the construction industry.”

This case study has not been fact-checked, but it has been edited for length, clarity, grammar, and style.

Download PDF

View the Agenda

View the Agenda

Book a Building Tour

Book a Building Tour

Book Your Exhibit Space

Book Your Exhibit Space

Explore the Exhibit Hall

Explore the Exhibit Hall

Become a Sponsor

Become a Sponsor

View Sponsors & Partners

View Sponsors & Partners

Reserve Hotel Rooms

Reserve Hotel Rooms

Discounted Plane Tickets

Discounted Plane Tickets

Read Case Studies

Read Case Studies

Download Past Reports

Download Past Reports